Critical Path Analysis (CPA), also known as network analysis, is a valuable project planning technique It is a technique used in project management for planning and monitoring project execution.

It helps identify all the essential tasks involved, organize them in the correct sequence, and pinpoint the critical path – the minimum time needed to complete the project.

Process of Critical Path Analysis (CPA)

The process of using Critical Path Analysis (CPA) involves the following steps:

- Define the project goal. Clearly outline the project’s objective. For instance, aiming to build a factory within six weeks.

- Break down into manageable tasks: Divide the project into smaller, sequential tasks. Create a network diagram to visualize the task order.

- Estimate task durations. Assign a time estimate to each task and incorporate these durations into the network diagram.

- Identify task dependencies. Analyze the network diagram to determine which tasks must be completed before others can begin.

- Pinpoint the critical path. Identify the sequence of tasks that must be finished on time for the entire project to be completed within the shortest timeframe. This is the critical path.

- Monitor project progress. Utilize the network diagram as a control tool to identify and address any delays or challenges that may arise during the project.

The critical path highlights the sequence of activities that absolutely must be completed on schedule for the project to be finished by the deadline. It essentially reveals the shortest possible timeframe for project completion.

Any delays in these critical tasks will directly impact the overall project timeline.

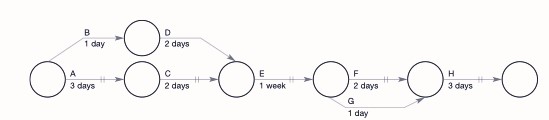

Example 1 – Easy Critical Path Analysis (CPA)

This project involves streamlining machine installation.

Let’s consider a scenario where a new machine needs to be installed and staff trained within three weeks (assuming a five-day workweek). Here is a breakdown of the steps involved and their estimated durations:

A: Remove out old machine (3 days)

B: Order new machine (1 day)

C: Prepare space for new machine (2 days)

D: Assemble new machine (2 days)

E: Install new machine (1 week)

F: Train workers (2 days)

G: Obtain raw materials (1 day)

H: Trial test run (3 days)

The network diagram reveals that Activity A and Activity B can start simultaneously – they are independent of each other. By examining the diagram with durations assigned, you can visually identify the critical path (marked with double lines) and confirm that the project can be completed within three weeks.

In this example, Activity A, Activity C, Activity E, Activity F and Activity H are critical. Delays in any of these tasks will push back the project timeline. Other activities, on the other hand, have some leeway (float time), meaning they can be rescheduled to an extent without impacting the overall deadline.

This float time can be strategically used in complex projects to optimize resource allocation.

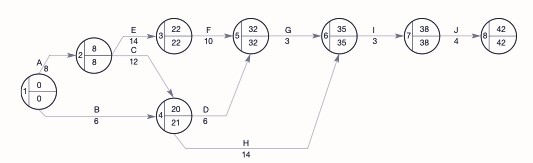

Example 2 – Difficult Critical Path Analysis (CPA)

This project involves constructing new house.

Imagine a project of building a house within 120 days. The tasks involved are broken down into ten key activities, like digging foundations and tiling the roof. Here, the order of tasks is crucial – the roof cannot be tiled before the walls are built.

The network diagram for this project would involve numbering each task for reference, followed by assigning durations to each activity. These durations are essential for calculating the critical path and identifying float time for non-critical tasks. The critical path is determined by calculating the earliest possible start time (EST) and latest allowable finish time (LFT) for each task.

Types of critical path methods for varied business needs

There are different Critical Path Analysis (CPA) methods depending on the project’s characteristics:

- Single time estimate. This method assumes known durations for each activity. It is used to estimate overall project time, individual task timelines, and slack time for non-critical tasks.

- Three activity time estimates. This method is used when activity durations are uncertain. It provides the same information as the single estimate method, along with probability information.

- Time-cost models. When time-cost trade-offs are crucial, this method comes into play. It helps determine the relationship between activity completion time and overall project cost. Time-cost models are used to identify the most cost-effective ways to minimize project completion time.

Advantages of Critical Path Analysis (CPA)

Benefits of Critical Path Analysis (CPA) include the following:

- Comprehensive planning. It encourages project managers to consider all project aspects, dependencies between tasks, and potential bottlenecks. This holistic view helps with making informed decisions.

- Versatility. It is adaptable to various project types and sizes. It can be used to solve a wide range of project management challenges by providing a clear visual representation of the project schedule, which can simplify complex projects.

- Improved efficiency. It promotes proactive planning, leading to smoother project execution. By minimizing downtime between tasks and identifying potential delays early on, it can enhance production efficiency and cash flow management.

Disadvantages of Critical Path Analysis (CPA)

Limitations of Critical Path Analysis (CPA) include the following:

- Execution matters rather than planning. A well-defined plan itself does not guarantee project success. The plan’s effectiveness depends heavily on the competency and motivation of the project team. Skilled management is crucial, especially when dealing with critical tasks that experience delays. Experienced managers need to be able to identify cost-effective ways to reallocate resources from non-critical tasks to address these delays.

- Complexity for large projects. For very large projects, creating and managing the network diagrams within Critical Path Analysis (CPA) can become cumbersome. While computer software can help manipulate complex networks and adjust activity durations, the initial investment of time and resources required to build the network in the software may be significant. The cost-effectiveness of using Critical Path Analysis (CPA) needs to be weighed against the potential for improved efficiency and cost savings.

- Data reliability. The accuracy of the Critical Path Analysis (CPA) analysis hinges on the reliability of the data used to construct the network diagrams. Consulting with team members during the planning stage to gather their input on activity durations can foster a sense of ownership and commitment to the plan. For entirely new projects with no past experience to draw from, estimating activity durations may involve a degree of guesswork.

By incorporating Critical Path Analysis (CPA) into your project management toolbox, you gain a valuable tool for planning, scheduling, and monitoring projects to ensure timely and efficient completion.

The main aim is to help decision-makers visualize the project workflow, identify critical tasks and optimize resource allocation.

Articles: 1,557 · Readers: 757,000 · Views: 2,260,160

Articles: 1,557 · Readers: 757,000 · Views: 2,260,160